AOD PUMP

R-AOD PUMPS

RANGE & TECHNICAL SPECIFICATIONS

| MODEL | R-AOD 15 | R-AOD 30 | R-AOD 40 | R-AOD 50 |

| MOC | AL/PP/SS/PVDF | AL/PP/SS/PVDF | AL/PP/SS/PVDF | AL/PP/SS/PVDF |

| DIAPHRAGM | PTFE/Santoprene | PTFE/Santoprene | PTFE/Santoprene | PTFE/Santoprene |

| SUCTION & DISCHARGE | 1⁄2 inch | 1 inch | 1.5 inch | 2 inch |

| AIR INLET | 1⁄4 inch | 1⁄4 inch | 1⁄2 inch | 1⁄2 inch |

| MAX FLOW | 35 LPM | 135 LPM | 270 LPM | 586 LPM |

| DISCHARGE PRESSURE (Kg/sq. cm) | 6 | 6 | 6 | 6 |

| HEAD (meter) | 60 | 60 | 60 | 60 |

| SUCTION LIFT (meter) | 1.8 | 3 | 5 | 5 |

| MAX SOLID SIZE in (mm) | 2.5 | 3.4 | 5 | 6.5 |

WORKING PRINCIPLE

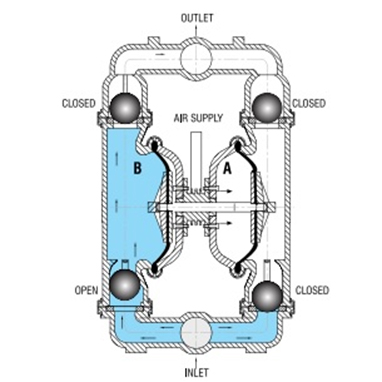

LEFT STROKE

When the pressurised diaphragm, diaphragm A, reaches the limit of its discharge stroke, the air valve redirects pressurised air to the back side of diaphragm B. The pressurised air forces diaphragm B away from the center block while pulling diaphragm A to the center block. Diaphragm B is now on its discharge stroke. Diaphragm B forces the inlet valve ball onto its seat due to the hydraulic forces developed in the liquid chamber and manifold of the pump.

These same hydraulic forces lift the discharge valve ball off its seat, while the opposite discharge valve ball is forced onto its seat, forcing fluid to flow through the pump discharge. The movement of diaphragm A toward the center block of the pump creates a vacuum within liquid chamber A. Atmospheric pressure forces fluid into the inlet manifold of the pump. The inlet valve ball is forced off its seat allowing the fluid being pumped to fill the liquid chamber.

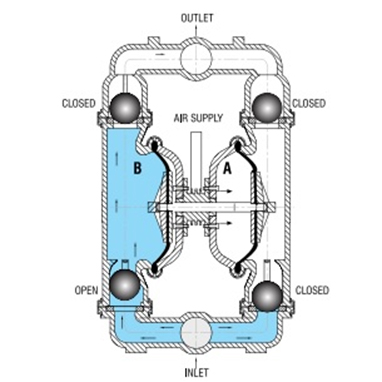

MID STROKE

The air valve directs pressurized air to the back side of diaphragm A. The compressed air is applied directly to the liquid column separated by elastomeric diaphragms. The diaphragm acts as a separation membrane between the compressed air and liquid, balancing the load and removing mechanical stress from the diaphragm. The compressed air moves the diaphragm away from the center block of the pump.

The opposite diaphragm is pulled in by the shaft connected to the pressurized diaphragm. Diaphragm B is on its suction stroke; air behind the diaphragm has been forced out to the atmosphere through the exhaust port of the pump. The movement of diaphragm B toward the center block of the pump creates a vacuum within chamber B. Atmospheric pressure forces fluid into the inlet manifold forcing the inlet valve ball off its seat. Liquid is free to move past the inlet valve ball and fill the liquid chamber (see shaded area).

AOD PUMPS CARVE

INDUSTRIES & APPLICATIONS

WASTE WATER TREATMENT

In the water treatment industry, diaphragm pumps are used in industrial and municipal wastewater treatment plants. Some fluids that are put into the pumps from wastewater treatment plants are high in viscosity and require pumps that can handle those liquids. Air operated double diaphragm pumps also help to pump polymers, acids, caustics and slurries during the water treatment process that are used to treat water.

FOOD & BEVERAGES

Air operated double diaphragm pump are used in the food and beverage industry for various food processing application. This pumps can be used for transferring food products like tomato pulp, chocolate, soft drinks, ham pulp, vinegar, pet food, yeast, eggs, vegetable oil, honey, vitamins, glucose syrup, concentrates, decaffeination, wine, fruit pulp, fruit juice, rennet, aromas and more.

Moreover, diaphragm pumps can be used also for pumping chemicals like caustic soda, nitric acid, hydrochloric acid, antioxidants and brine and waste products like animal blood, waste water and sludge. They find application in the food processing, CIP (cleaning in place) plants, and waste water treatment and slaughtering.

PAINTS & COATING

AODD pump are also used in the paint industry considering their ability to move viscous fluids like ink, acrylic, primers and coatings. Moreover air pumps are capable of transferring solvents for washing systems and waste fluids. The main applications that we can find in this field are printing machines, inks maker, spray systems and cleaning baths.

PAINTS & COATING

In the Pharma field air operated double diaphragm pump is one of the main systems for pumping fluids considering that a large part of them contain particles and have high viscosity. For this reason, AODD pump can handle chemicals, proteins, enzymes, vitamins, vegetable extracts, flavours, ointments, alcohols, blood plasma, additives, disinfectants, waste solvents, waste fluids and more. The main applications are filtering aids, ultrafiltration, aseptic transfer, tablet coating, distillation plant, reactors for the production and waste water treatment.